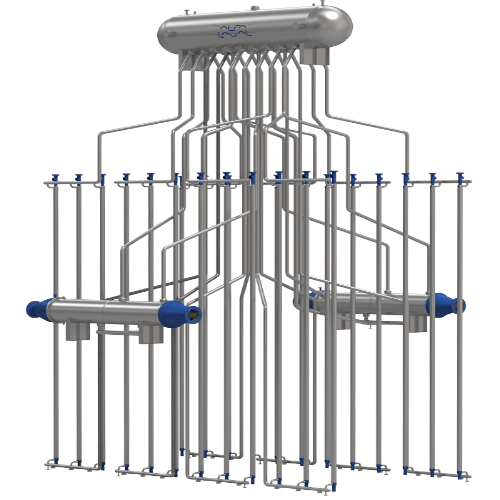

Heat Recovery Unit

Product Details:

- Weight 200 Kilograms (kg)

- Usage Air Compressor & Wastewater

- Product Type Heat Recovery Unit

- Size 1 meter by 1 meter

- Material Other

- Type Industrial

- Installation Type Other

- Click to View more

Heat Recovery Unit Price And Quantity

- 1 Unit

Heat Recovery Unit Product Specifications

- Industrial

- Other

- 200 Kilograms (kg)

- 1 meter by 1 meter

- Heat Recovery Unit

- Other

- Air Compressor & Wastewater

Heat Recovery Unit Trade Information

- 10 Unit Per Month

- 15-20 Days

Product Description

FAQs on Heat Recovery Units

1. What is a Heat Recovery Unit (HRU)?

A Heat Recovery Unit (HRU) is a system designed to capture and reuse waste heat from industrial processes, ventilation systems, or other sources. It transfers the recovered heat to incoming air or fluids, improving energy efficiency and reducing overall heating costs.

2. How does a Heat Recovery Unit work?

An HRU operates by using a heat exchanger to transfer thermal energy from a hot exhaust or waste stream to a cooler incoming stream. The basic concept is represented by the formula for heat transfer efficiency:

ΔT\Delta T = Temperature difference between the hot and cold streams3. What types of heat can be recovered using an HRU?

HRUs can recover heat from various sources, including:

- Exhaust Air: Captures heat from air being expelled from ventilation systems.

- Industrial Processes: Recovers heat from manufacturing or production processes.

- Hot Water or Wastewater: Utilizes heat from hot water or wastewater streams.

- Exhaust Gases: Retrieves heat from gases released during combustion or other processes.

-

4. What are the benefits of using a Heat Recovery Unit?

- Energy Savings: Reduces the amount of energy required for heating, leading to lower utility bills.

- Cost Reduction: Decreases operational costs by reusing heat that would otherwise be wasted.

- Environmental Impact: Supports sustainability efforts by lowering overall energy consumption and reducing emissions.

- Improved Efficiency: Enhances the performance of heating systems and industrial processes.

- Increased Comfort: Maintains consistent temperatures in indoor environments.

-

5. What types of heat exchangers are used in HRUs?

HRUs typically use one of the following heat exchanger types:

- Plate Heat Exchangers: Compact and efficient, suitable for various applications.

- Shell and Tube Heat Exchangers: Robust and capable of handling larger volumes and higher pressures.

- Rotary Heat Exchangers: Utilize a rotating wheel to transfer heat between the exhaust and incoming air streams.

-

6. Where can Heat Recovery Units be used?

HRUs are versatile and can be used in:

- HVAC Systems: To preheat fresh air in commercial and residential buildings.

- Industrial Facilities: To recover heat from production processes and reduce heating costs.

- Commercial Buildings: To improve energy efficiency in large buildings with significant ventilation needs.

- Wastewater Treatment Plants: To capture heat from wastewater for process heating.

-

7. What factors should be considered when selecting an HRU?

Consider the following factors:

-

Heat Source: Type and temperature of the waste heat available.

-

Heat Transfer Efficiency: Performance of the heat exchanger in recovering and transferring heat. The formula for efficiency is:

η=QrecoveredQinput\eta = \frac{Q_{\text{recovered}}}{Q_{\text{input}}} - Qinput = Amount of heat available for recovery

-

Size and Capacity: Matching the HRU to the specific heating requirements of your system.

-

Installation Space: Ensuring the unit fits within the available space.

-

Maintenance Requirements: Ease of access for servicing and upkeep.

-

8. How do HRUs contribute to sustainability efforts?

HRUs contribute to sustainability by:

- Reducing Energy Consumption: By reusing waste heat, they lower the demand for additional heating.

-

- Minimizing Waste: They reduce the amount of heat wasted in industrial and commercial processes.

-

- Lowering Carbon Footprint: Decreasing energy use leads to reduced greenhouse gas emissions.

-

9. What maintenance is required for a Heat Recovery Unit?

Routine maintenance includes:

- Cleaning Heat Exchangers: To ensure efficient heat transfer and prevent fouling.

- Inspecting and Replacing Filters: To maintain airflow and heat transfer efficiency.

- Checking for Leaks: Ensuring there are no leaks in the system that could affect performance.

- Regular Inspections: Performing periodic checks to ensure all components are functioning correctly.

-

10. Can an HRU be integrated with existing systems?

Yes, HRUs can be integrated with existing HVAC systems, industrial processes, and commercial buildings. They are designed to work with various types of systems and can be customized to fit specific requirements.

These FAQs provide a comprehensive overview of Heat Recovery Units and include relevant formulas for better understanding their operation and efficiency. Let me know if you need more details or additional questions!

Send Inquiry

Send Inquiry Send SMS

Send SMS