Heat Recovery In Paper Industry

Product Details:

- Type Industrial

- Click to View more

Heat Recovery In Paper Industry Price And Quantity

- 1 Number

Heat Recovery In Paper Industry Product Specifications

- Industrial

Heat Recovery In Paper Industry Trade Information

- 10 Number Per Year

- 15-20 Days

Product Description

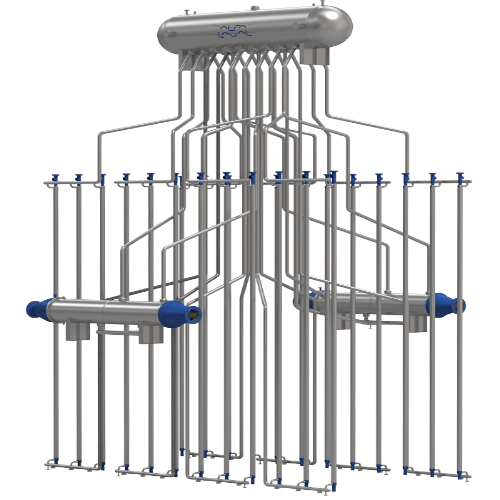

In the paper industry, a Heat Recovery Unit (HRU) is employed to capture and utilize waste heat generated during various stages of the manufacturing process. The paper production process involves significant thermal energy use, and substantial amounts of heat are often lost through exhaust gases, hot water, and other byproducts.

An HRU is designed to intercept this waste heat and transfer it to a usable medium. This typically involves using heat exchangers, where thermal energy from hot waste streams is transferred to a fluid (such as water or air) that can be used elsewhere in the process. For instance, recovered heat can be employed to preheat water used in the process, reduce the need for additional heating, or improve the efficiency of other systems.

Implementing an HRU in the paper industry not only enhances energy efficiency by reducing the demand for external energy sources but also lowers operational costs by making better use of the heat that would otherwise be wasted. Additionally, it contributes to environmental sustainability by decreasing the industry's overall energy consumption and reducing greenhouse gas emissions. By integrating heat recovery into their operations, paper manufacturers can achieve significant economic and environmental benefits.

FAQs on Heat Recovery in the Paper Industry

1. What is heat recovery in the paper industry?

Heat recovery in the paper industry involves capturing waste heat generated during various stages of paper production, such as drying and pulping, and reusing it for other processes like preheating water, generating steam, or heating buildings.

2. How does heat recovery work in the paper industry?

Heat exchangers capture heat from exhaust gases, steam, or other hot by-products of the papermaking process. This recovered heat can be used for preheating process water, generating steam, or drying the paper, improving overall energy efficiency.

3. What are the benefits of heat recovery in the paper industry?

- Energy Efficiency: Reuses waste heat, reducing the need for additional fuel or energy.

- Cost Savings: Lowers energy costs by utilizing recovered heat, reducing fuel consumption.

- Reduced Emissions: Minimizes greenhouse gas emissions by improving energy use.

- Process Optimization: Improves the efficiency of drying and steam generation, key stages in papermaking.

4. What stages of paper production benefit most from heat recovery?

- Drying Process: A significant amount of energy is used to dry the paper, and heat recovery can reclaim much of the waste heat from drying cylinders.

- Steam Generation: Waste heat can be used to preheat water or generate steam for other parts of the process.

- Pulping: Heat recovery systems can capture heat from exhaust gases during the pulping stage.

5. What types of heat recovery systems are used in the paper industry?

- Air-to-Air Heat Exchangers: Transfer heat from exhaust air to incoming fresh air, reducing heating energy needs.

- Air-to-Water Heat Exchangers: Recover heat from air to preheat water used in the papermaking process.

- Condensate Recovery Systems: Capture heat from steam condensate for reuse in preheating or steam generation.

6. What factors should be considered when designing a heat recovery system for the paper industry?

- Source of Waste Heat: Identify the processes generating the most waste heat, such as drying or steam systems.

- Heat Demand: Assess where recovered heat can be efficiently reused, such as preheating water or air.

- System Compatibility: Ensure the heat recovery system is compatible with existing equipment and infrastructure.

- Environmental Conditions: Consider the operating temperatures and humidity levels in the plant.

7. How much energy can be saved through heat recovery in the paper industry?

The amount of energy saved depends on the efficiency of the heat recovery system and the scale of the plant. In some cases, heat recovery can reduce energy consumption by 10-30%, leading to significant cost savings.

8. How does heat recovery contribute to sustainability in the paper industry?

Heat recovery reduces the need for fossil fuels, lowering carbon emissions and overall energy use. It supports the industry™s move toward more sustainable and environmentally friendly operations.

9. What maintenance is required for a heat recovery system in the paper industry?

- Regular Cleaning: Prevent buildup in heat exchangers to maintain efficiency.

- Inspection of Heat Exchangers: Ensure there is no corrosion or damage.

- System Monitoring: Continuously track performance to ensure optimal heat recovery.

10. Can heat recovery systems be retrofitted to existing paper production facilities?

Yes, heat recovery systems can often be integrated into existing processes with minimal disruption, improving energy efficiency without the need for major overhauls to the production line.

Send Inquiry

Send Inquiry Send SMS

Send SMS