Heat Recovery from Open Cooling Tower

Product Details:

Heat Recovery from Open Cooling Tower Price And Quantity

- 1 Number

- 100000 INR/Number

Product Description

Heat recovery from an open cooling tower is a process designed to enhance energy efficiency by utilizing the thermal energy that is typically expelled into the environment. Open cooling towers are commonly used in industrial and commercial settings to reject excess heat from water-cooled systems. However, the heat rejected by these towers can be captured and repurposed to benefit other processes.

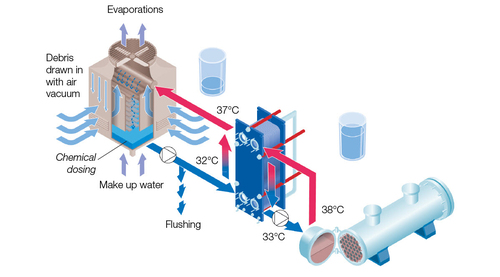

The heat recovery system typically involves installing a heat exchanger or similar device that transfers thermal energy from the cooling towerïs discharge water to a secondary medium, such as water or air. This recovered heat can then be used for various purposes, including pre-heating process water, space heating, or even generating additional power in combined heat and power (CHP) systems.

By capturing and reusing the heat from the cooling tower, businesses can significantly reduce their energy consumption, lower utility bills, and decrease their environmental footprint. This approach not only enhances overall operational efficiency but also supports sustainability goals by minimizing waste heat and reducing greenhouse gas emissions.

FAQs on Heat Recovery from Open Cooling Towers

1. What is heat recovery from an open cooling tower?

Heat recovery from an open cooling tower involves capturing waste heat from the cooling process, where water is cooled by evaporation, and repurposing it for other uses, such as preheating water, heating buildings, or industrial processes.

2. How does heat recovery from an open cooling tower work?

Heat exchangers capture the warm water or air exiting the cooling tower and transfer that heat to another system, such as preheating process water or heating air, thereby reusing energy that would otherwise be lost.

3. What are the benefits of heat recovery from an open cooling tower?

- Energy Savings: Reduces the need for additional energy by reusing waste heat.

- Cost Reduction: Lowers operating costs by cutting down on fuel or energy use.

- Increased Efficiency: Enhances the overall efficiency of cooling and heating systems.

- Environmental Impact: Reduces greenhouse gas emissions by making better use of existing energy.

4. What types of heat exchangers are used in cooling tower heat recovery?

- Plate Heat Exchangers: Compact and efficient, ideal for transferring heat between cooling water and other fluids.

- Air-to-Water Heat Exchangers: Capture heat from the air leaving the cooling tower and transfer it to water for heating purposes.

- Shell and Tube Heat Exchangers: Common for handling larger volumes of water with higher temperatures.

5. What industries benefit from heat recovery from cooling towers?

Industries like:

- Power Generation: Use cooling towers extensively and can benefit from heat recovery to preheat water for steam generation.

- Manufacturing: Reuse waste heat for process heating or preheating feedwater.

- Commercial Buildings: Reuse heat for building heating, water heating, or HVAC systems.

6. How much energy can be recovered from a cooling tower?

The amount of recoverable energy depends on the temperature of the water and the efficiency of the heat recovery system. In many cases, cooling towers can provide a significant source of waste heat that can be reused elsewhere in the facility.

7. What factors should be considered when designing a cooling tower heat recovery system?

- Water Temperature: Higher temperature water exiting the cooling tower provides more recoverable heat.

- Heat Demand: Identify processes or systems that can benefit from the recovered heat.

- System Compatibility: Ensure the heat exchanger fits the existing infrastructure.

- Water Quality: Consider water treatment to prevent scaling or fouling in the heat exchanger.

8. How does heat recovery from a cooling tower contribute to sustainability?

By capturing and reusing waste heat, cooling tower heat recovery systems reduce the need for external energy sources, lower greenhouse gas emissions, and improve the overall sustainability of industrial operations.

9. What maintenance is required for a heat recovery system from a cooling tower?

- Regular Inspection: Check for fouling, scaling, or corrosion in the heat exchanger.

- Cleaning: Keep the heat exchanger and cooling tower surfaces clean to maintain efficiency.

- Water Quality Management: Use water treatment to minimize buildup and maintain efficient heat transfer.

10. Can heat recovery systems be retrofitted into existing cooling towers?

Yes, heat recovery systems can be added to existing cooling tower setups with minimal modifications, allowing facilities to improve their energy efficiency without major operational changes.

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free