Heat Recovery from Effluent

Product Details:

- Type Industrial

- Click to View more

Heat Recovery from Effluent Price And Quantity

- 1 Number

Heat Recovery from Effluent Product Specifications

- Industrial

Heat Recovery from Effluent Trade Information

- 10 Number Per Year

- 15-20 Days

Product Description

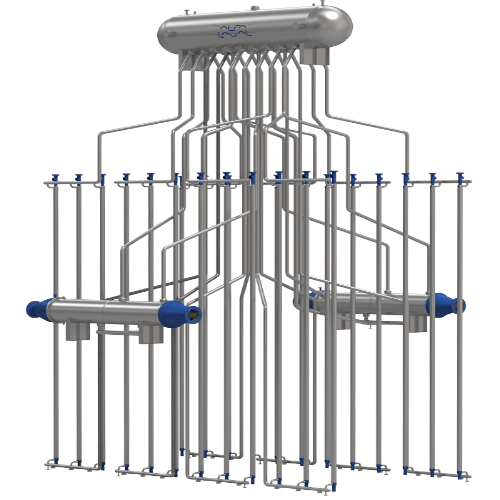

Heat recovery from effluent is a process designed to enhance energy efficiency in industrial settings by utilizing the thermal energy present in waste streams. Effluent, which is often hot due to various industrial processes, carries significant thermal energy that can be harnessed rather than wasted. The process typically involves the installation of heat exchangers or recovery systems that transfer heat from the hot effluent to a secondary medium, such as water or air. This recovered heat can then be used for various purposes, including pre-heating fluids, powering heating systems, or improving overall process efficiency.

Implementing heat recovery systems not only reduces energy consumption and operational costs but also contributes to environmental sustainability by lowering greenhouse gas emissions. By capturing and repurposing waste heat, industries can improve their energy footprint, comply with regulatory requirements, and enhance their overall efficiency.

FAQs on Heat Recovery from Effluent

1. What is heat recovery from effluent?

Heat recovery from effluent involves capturing waste heat from industrial or wastewater effluents and repurposing it to improve energy efficiency. This process recovers heat from hot liquids discharged during industrial operations or wastewater treatment.

2. How does heat recovery from effluent work?

Heat exchangers are used to transfer heat from the hot effluent to another medium, such as water or air, which can then be used for heating purposes or other industrial processes. The recovered heat can be used to preheat incoming fluids or generate steam.

3. What are the benefits of heat recovery from effluent?

- Energy Savings: Reduces the need for additional energy by utilizing waste heat.

- Cost Reduction: Lowers operational costs by reducing the need for external heating sources.

- Improved Efficiency: Enhances overall energy efficiency of industrial processes.

- Environmental Impact: Reduces the environmental footprint by recovering heat that would otherwise be wasted.

4. What types of heat exchangers are used for effluent heat recovery?

- Shell and Tube Heat Exchangers: Suitable for high-temperature effluents and large volumes.

- Plate Heat Exchangers: Compact and efficient for transferring heat between fluids.

- Spiral Heat Exchangers: Effective for handling viscous or particulate-laden effluents.

5. What industries benefit from heat recovery from effluent?

Industries such as:

- Chemical Manufacturing: Reuse heat from process effluents to preheat process streams or generate steam.

- Food and Beverage: Capture heat from wastewater for energy recovery or process heating.

- Pulp and Paper: Utilize heat from effluent streams in paper production processes.

- Textile: Recover heat from dyeing and washing processes to reduce energy consumption.

6. What factors should be considered when designing a heat recovery system for effluent?

- Effluent Temperature: Higher temperatures provide more recoverable heat.

- Effluent Composition: Consider potential corrosive or fouling effects on heat exchanger materials.

- System Compatibility: Ensure the heat recovery system integrates well with existing processes.

- Heat Demand: Identify where recovered heat can be efficiently used within the facility.

7. How much energy can be recovered from effluent?

The amount of recoverable energy depends on the temperature of the effluent and the efficiency of the heat recovery system. In many cases, a significant portion of the waste heat can be reclaimed and used, leading to considerable energy savings.

8. How does heat recovery from effluent contribute to sustainability?

By capturing and reusing waste heat, heat recovery systems help reduce the need for external energy sources, lower greenhouse gas emissions, and support more sustainable industrial practices.

9. What maintenance is required for a heat recovery system from effluent?

- Regular Inspection: Check for fouling, scaling, or corrosion in the heat exchanger.

- Cleaning: Clean the heat exchanger periodically to maintain efficient heat transfer.

- System Monitoring: Continuously monitor system performance to ensure effective heat recovery.

10. Can heat recovery systems be retrofitted to existing processes?

Yes, heat recovery systems can often be integrated into existing processes with appropriate modifications, improving energy efficiency without major disruptions to current operations.

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free