Chiller Condenser Protection

Product Details:

Chiller Condenser Protection Price And Quantity

- 1 Number

- 500000 INR/Number

Chiller Condenser Protection Trade Information

- All India

Product Description

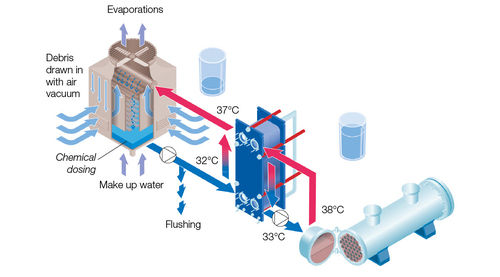

Chiller Condenser Protection involves a series of preventive measures and maintenance practices designed to safeguard the condenser unit of a chiller from various forms of damage and inefficiency. The condenser, a critical component in the chiller system, is responsible for dissipating heat absorbed during the cooling process. Protecting this unit is essential for maintaining optimal performance and extending its operational lifespan.

Key protection strategies include:

- Anti-Corrosive Coatings: Applying protective coatings to condenser coils helps prevent damage from environmental factors such as moisture, chemicals, or saline conditions.

- Regular Cleaning: Routine cleaning of the condenser coils and fins removes dirt, debris, and other contaminants that can impair heat transfer and reduce efficiency.

- Filtration Systems: Installing filters helps capture airborne debris, minimizing fouling and ensuring efficient heat exchange.

- Freeze Protection: Implementing heating or insulation solutions prevents damage to the condenser coils in freezing conditions.

- Mechanical Checks: Regular inspections and maintenance of associated components, such as fans and sensors, ensure the overall health of the condenser system.

By adopting these protective measures and adhering to a regular maintenance schedule, facilities can prevent common issues such as corrosion, fouling, and mechanical damage. This not only enhances the efficiency of the chiller system but also reduces energy consumption and operational costs, contributing to a more sustainable and reliable cooling solution.

Effective chiller condenser protection is crucial for avoiding costly repairs and ensuring the long-term reliability of the cooling system.

FAQs on Chiller Condenser Protection

1. What is chiller condenser protection?

Chiller condenser protection refers to measures and systems put in place to safeguard the condenser unit of a chiller from damage and inefficiencies caused by external factors, operational issues, or environmental conditions.

2. Why is protecting the chiller condenser important?

Protecting the condenser is crucial for maintaining efficient chiller operation, preventing premature wear and tear, reducing maintenance costs, and ensuring the longevity of the chiller system. A well-protected condenser also improves overall system performance and energy efficiency.

3. What are common threats to chiller condensers?

- Corrosion: Caused by exposure to moisture, chemicals, or saline environments.

- Fouling: Buildup of dirt, debris, or scale that impairs heat transfer.

- Mechanical Damage: Damage from physical impacts or debris.

- Freezing: Low temperatures that can cause damage to the condenser coils.

- Blockage: Obstruction of airflow or water flow, reducing condenser efficiency.

4. What methods are used for chiller condenser protection?

- Protective Coatings: Apply anti-corrosive coatings to condenser coils to prevent corrosion.

- Filtration Systems: Install filters to catch airborne debris and prevent fouling.

- Regular Cleaning: Perform routine cleaning of coils and fins to remove dirt and debris.

- Heat Exchanger Maintenance: Regularly inspect and clean heat exchangers to maintain efficiency.

- Freeze Protection: Implement heating or insulation solutions to prevent freezing in cold climates.

5. How often should chiller condensers be inspected?

Chiller condensers should be inspected regularly, typically every 6 to 12 months, depending on the operating conditions and manufacturer recommendations. More frequent inspections may be required in harsh environments or high-load conditions.

6. What should be included in a chiller condenser maintenance routine?

- Visual Inspection: Check for signs of damage, corrosion, or blockage.

- Cleaning: Remove debris and dirt from coils and fins.

- Component Checks: Inspect and test associated components, such as fans and sensors.

- Performance Monitoring: Assess the performance of the condenser and the overall chiller system.

- Preventive Measures: Apply protective coatings and other preventative measures as needed.

7. How can I prevent corrosion of the chiller condenser?

- Use Corrosion-Resistant Materials: Opt for condensers made from materials resistant to corrosion.

- Apply Protective Coatings: Use anti-corrosive coatings on condenser surfaces.

- Maintain Proper Drainage: Ensure proper drainage to prevent water accumulation around the condenser.

- Monitor Environmental Conditions: In corrosive environments, implement additional protection measures.

8. What are the signs of condenser problems that need attention?

- Reduced Cooling Efficiency: Decreased performance or inability to maintain desired temperatures.

- Increased Energy Consumption: Higher energy use due to reduced efficiency.

- Unusual Noises: Strange noises indicating mechanical issues or debris.

- Visible Damage: Signs of physical damage, corrosion, or fouling on the condenser.

9. Can I perform condenser protection and maintenance myself?

Basic tasks, such as cleaning and visual inspections, can often be performed by facility staff. However, more complex maintenance and protective measures should be carried out by qualified technicians to ensure proper handling and effectiveness.

10. How can I find a professional for chiller condenser protection and maintenance?

- Check References: Look for recommendations and reviews from other customers.

- Verify Credentials: Ensure the technician or service provider has relevant certifications and experience.

- Request Quotes: Obtain quotes from multiple providers to compare services and costs.

- Evaluate Services: Choose a provider offering comprehensive protection and maintenance services.

Send Inquiry

Send Inquiry Send SMS

Send SMS