Boiler Protection Gasket Plate Heat Exchanger

Product Details:

Boiler Protection Gasket Plate Heat Exchanger Price And Quantity

- 1 Number

Product Description

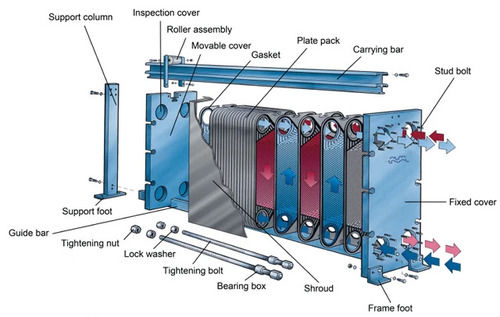

Boiler Protection Gasket Plate Heat Exchanger is engineered to enhance boiler protection and performance through advanced heat exchange technology. This heat exchanger utilizes a gasketed plate design to facilitate effective heat transfer between two fluids while maintaining a robust barrier to prevent leaks and contamination.

Key Features:

- Gasket Plate Design: Provides a reliable and efficient method for heat transfer, reducing the risk of leaks and improving thermal performance.

- Enhanced Protection: Safeguards boilers from operational issues by maintaining optimal temperature control and preventing potential damage caused by heat transfer inefficiencies.

- Versatile Applications: Suitable for various industrial settings where effective heat exchange and boiler protection are critical.

- Ease of Maintenance: The gasketed plate construction allows for straightforward cleaning and maintenance, ensuring long-term reliability and efficiency.

By integrating a Boiler Protection Gasket Plate Heat Exchanger into your system, you can improve boiler efficiency, extend equipment lifespan, and reduce maintenance costs while ensuring the safe and reliable operation of your industrial processes.

FAQs

1. What is a Boiler Protection Gasket Plate Heat Exchanger?

A Boiler Protection Gasket Plate Heat Exchanger is a heat exchanger designed to protect boilers by efficiently transferring heat between fluids through a gasketed plate construction, minimizing the risk of leaks and enhancing thermal performance.

2. How does the gasket plate design improve performance?

The gasket plate design ensures effective heat transfer by providing a secure seal between plates, which prevents leaks and maintains the integrity of the heat exchange process. This design enhances overall thermal efficiency and reliability.

3. What are the main benefits of using this heat exchanger?

- Enhanced Protection: Helps prevent leaks and damage to the boiler.

- Improved Efficiency: Increases thermal performance and heat transfer.

- Reduced Maintenance: Simplifies cleaning and upkeep due to the gasketed plate design.

- Versatility: Suitable for various industrial applications.

4. How often should the heat exchanger be maintained?

Regular maintenance is recommended every 6 to 12 months, depending on the operational conditions and manufacturer guidelines. This includes cleaning and inspecting the gasket plates to ensure optimal performance.

5. Can the heat exchanger be retrofitted to existing systems?

Yes, the Boiler Protection Gasket Plate Heat Exchanger can often be integrated into existing systems with appropriate modifications, improving heat exchange efficiency and boiler protection.

6. What types of industries benefit from this heat exchanger?

Industries such as manufacturing, chemical processing, and energy production can benefit from the enhanced heat transfer and boiler protection provided by this heat exchanger.

7. How does this heat exchanger contribute to energy savings?

By improving heat transfer efficiency and reducing the risk of leaks, the heat exchanger helps to optimize boiler performance, which can lead to lower energy consumption and cost savings.

8. What should be done if a leak or issue is detected?

If a leak or issue is detected, the heat exchanger should be inspected and serviced by a qualified technician to address any problems and ensure continued efficient operation.

9. What materials are used in the construction of the heat exchanger?

The heat exchanger is typically constructed using high-quality, corrosion-resistant materials designed to withstand harsh industrial environments and ensure long-term reliability.

10. How can I find a qualified service provider for maintenance?

Look for service providers with experience in heat exchanger maintenance, check reviews and certifications, and ask for recommendations from industry peers or equipment suppliers.

Send Inquiry

Send Inquiry Send SMS

Send SMS